Residential

Balustrades / barrier rails / handrails / pool rails / ramp rails

Durable construction

By default our balustrades and rails are fully welded, and made either from 316 (i.e. marine) grade stainless steel or brass - see our Bell Stainless | Brassworx website for more info on this material - for both indoor and outdoor use. Fully welding ensures long life for the asset in question, even in harsh environments like salty coastal areas.

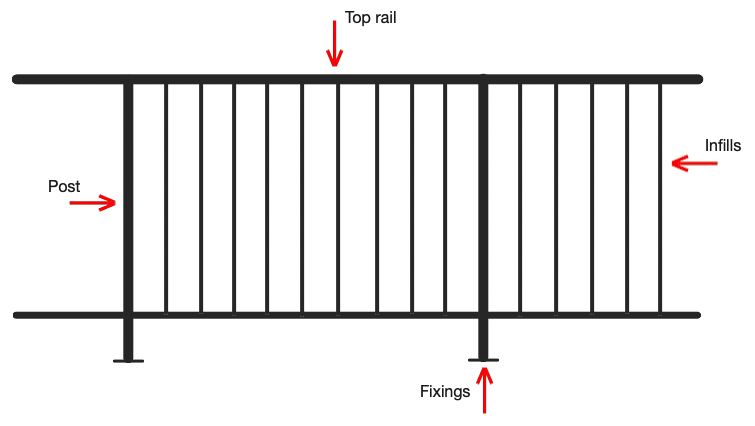

There are 4 areas to consider when designing balustrades

• Top rail - round tube | oval tube (not always available) | square tube | flat bar | brackets for timber (supplied by others).

• Posts - round tube | square tube | flat bar.

• Infills - solid round bar | stainless wire | glass | etc.

• Fixings - round plates with or without covers | square plates | concealed fixings | etc.

Things to consider

Grade and surface finish of stainless steel make a big difference to how your balustrade or rail will look over time, especially in harsh environments containing high concentrations of contamininants such as salt or chlorine.

A smoother (i.e. more highly polished) surface is more expensive initially, but will remain looking new much longer than a surface with a rougher (i.e. less highly polished) surface finish.

There are legislated safety requirements for different types of balustrades, barrier rails, handrails, pool rails or ramp rails. The precise specifications needed are directly related to the type of rail and its surroundings.

We can help design a balustrade or rail suited to the rest of a building's architecture that will meet all relevant Australian Standards. If you're not sure what you require, be sure to ask a member of our experienced sales team.

Swimming pool rails can occasionally highlight pre-existing issues. We suggest only using 316 (i.e. marine) grade, mirror polished stainless steel for this purpose, with earth tags welded to posts, and only fixed down with 316 grade stainless steel fixings. In some problem cases it may be necessary to have the pool water tested by a qualified person for residual low-level electrical leakage which can cause premature deterioration of stainless steel.

These are specialist areas that Bell Stainless has no direct expertise in, but in these cases we're happy to do what we can to ensure the integrity of the stainless steel.